What is a Laser Cutting Machine and How Does It Work?

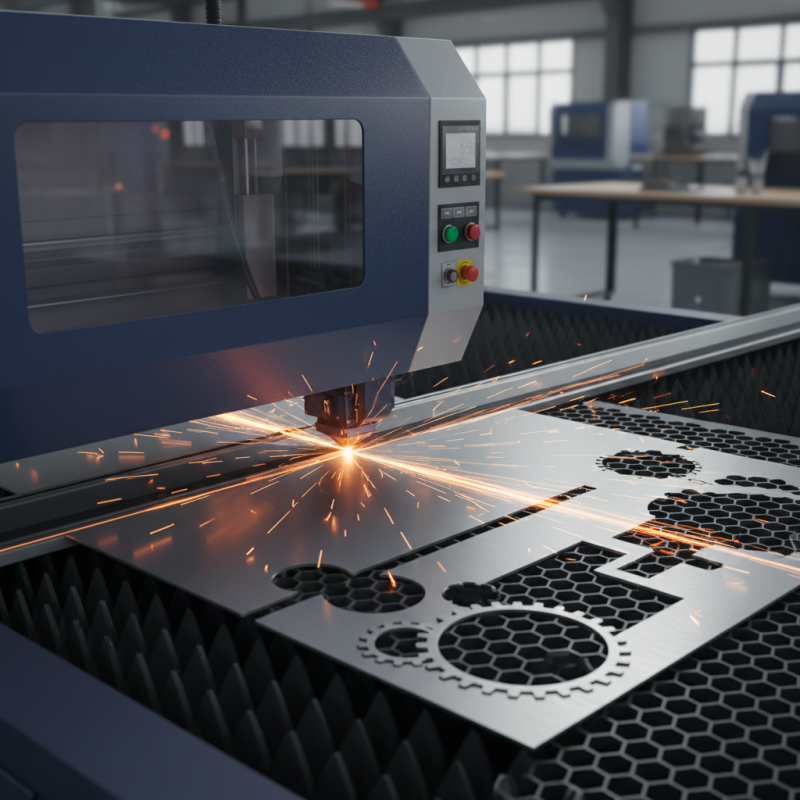

A laser cutting machine is an advanced tool that has revolutionized manufacturing and design. It uses focused light to cut through materials with precision. This technology can handle various materials, such as metal, wood, and plastic.

When properly utilized, a laser cutting machine can produce intricate designs and sharp edges. The process involves a high-powered laser beam that melts or vaporizes the material. However, it is important to remember that not every project requires this technology. Mistakes can happen if the wrong settings are used.

Companies often face challenges in maximizing the efficiency of laser cutting machines. Each material reacts differently to the laser, which can lead to inconsistencies. Understanding the machine's capabilities and limitations is crucial for achieving the best results.

What is a Laser Cutting Machine?

A laser cutting machine is a powerful tool that uses focused light to cut various materials. This technology has revolutionized manufacturing processes across industries. It works by directing a high-intensity laser beam onto a material's surface. The beam melts, burns, or vaporizes the material along the cutting path. This method is highly precise, producing clean edges and intricate designs.

Laser cutting machines excel with materials like metal, wood, and plastic. They can create complex shapes that traditional cutting tools struggle with. Operators must ensure proper settings for different materials. Mistakes in settings can lead to uneven cuts or damage. Users often need to refine their techniques over time. It's not always perfect.

The versatility of laser cutting appeals to many sectors. Artists can use it for stunning designs. Engineers find it valuable for prototypes. However, the machines require regular maintenance. Neglect can result in decreased performance. For those new to laser cutting, practice and patience are key to mastering this technology. Each project is an opportunity to learn and improve.

Key Components of Laser Cutting Machines

Laser cutting machines are intricate tools designed to cut materials with high precision using focused laser beams. The key components of these machines include the laser source, optics, and a motion system. The laser source generates the intense beam that cuts through materials. Common sources include CO2 lasers and fiber lasers. Each has its strengths for different materials.

Optics play a vital role in directing the laser beam. This usually involves lenses and mirrors that focus the beam onto the workpiece. The quality of these optics greatly affects the cut edge's precision and smoothness. An effective motion system synchronizes the laser movement across the material, ensuring accurate cuts at high speeds.

Operators must ensure that all components work harmoniously. Tuning the settings for different materials can be challenging. Small adjustments can lead to significant differences in quality. Users often find themselves tweaking parameters for ideal results. Regular maintenance of these components is essential, but it is also an area where mistakes happen. Overlooking small issues can lead to inefficient cuts or equipment failure.

What is a Laser Cutting Machine and How Does It Work? - Key Components of Laser Cutting Machines

| Component | Description | Function |

|---|---|---|

| Laser Source | Generates the laser beam, typically using CO2 or fiber technology. | Provides the energy needed for cutting materials. |

| Optics | Includes lenses and mirrors that focus and direct the laser beam. | Enhances precision and control during the cutting process. |

| Motion System | Consists of motors and drives that move the laser head and/or material. | Allows for the desired cutting path and shapes. |

| Control System | Includes software and hardware to operate the laser machine. | Manages cutting parameters and patterns based on designs. |

| Exhaust System | Removes smoke, fumes, and debris produced during cutting. | Maintains a clean work environment and improves visibility. |

Types of Laser Cutting Technologies Explained

Laser cutting technology has evolved significantly, offering various methods tailored for specific applications. The primary types of laser cutting include CO2 lasers, fiber lasers, and solid-state lasers. Each type has unique advantages and is suited for different materials.

CO2 lasers are highly efficient for cutting non-metal materials such as wood, glass, and acrylic. They use a gas mixture, which generates a powerful laser beam. These lasers are versatile but may struggle with thicker metal. Fiber lasers, on the other hand, excel in cutting metal. They produce a high-quality beam and have lower operational costs. Solid-state lasers represent another option, providing precision cutting for specific industrial needs.

Tip: Always assess your material type before choosing a laser cutting technology. Material thickness can greatly influence cutting quality and speed.

When selecting a machine, consider the cut's quality and the machine's maintenance needs. Not all machines handle every task. Some may require frequent adjustments or calibration. This might not be evident initially but can lead to challenges over time.

Tip: Test different settings before a major project to find the optimal configuration. This will help avoid waste and improve efficiency in production.

Laser Cutting Machines: Types and Applications

The Laser Cutting Process: Step-by-Step Breakdown

The laser cutting process is a remarkable technology used in various industries today. It involves several key steps that allow for precision and efficiency. Initially, a design is created using computer-aided design (CAD) software. This software allows engineers to visualize the final product accurately. According to industry reports, laser cutting machines have increased production efficiency by up to 20% in some sectors.

Once the design is ready, the next step is to select the appropriate materials. Common materials include metals, plastics, and wood. Each material requires specific settings for power, speed, and frequency. Factors such as thickness and density play significant roles in determining these settings. It's essential to note that improper settings can lead to imperfections like rough edges or incomplete cuts, which can affect the final product's quality.

After setup, the machine follows the programmed path, using focused laser beams to cut through the material. This part of the process is crucial. Any deviation can result in wasted material or extensive downtime for recalibration. Reports show that an estimated 60% of issues in laser cutting arise from setup mistakes. Attention to detail is vital for achieving the desired outcomes. Adjustments may need to be made on-the-fly, depending on how the material responds to the laser.

Applications and Industries Utilizing Laser Cutting Machines

Laser cutting machines are versatile tools used in various industries. They work by directing a high-powered laser beam to cut through materials. This technology is popular in sectors like manufacturing, automotive, and aerospace.

In manufacturing, these machines create precise cuts in metals and plastics. They offer efficiency and reduce waste. For the automotive sector, laser cutting shapes components with high accuracy. This process supports quicker production times and improved vehicle designs. Meanwhile, in aerospace, laser cutting is vital for creating lightweight structures. It helps engineers meet strict specifications while maintaining performance.

However, challenges exist. Not all materials respond well to laser cutting. Some can melt or warp. This unpredictability requires careful material selection and testing. In addition, laser cutting can produce harmful fumes. Adequate ventilation is necessary to ensure workplace safety. Overall, while the technology is beneficial, it demands ongoing refinement and consideration.